Partner for the development and manufacture of demanding subassemblies

Expertise in molded solutions

We are experts in various materials and advanced vacuum forming, thermoforming and polyurethane molding methods, with decades of experience. We operate like our customers, in accordance with quality standards and sustainable development values, improving our operations on an ongoing basis.

Helping our customers

We serve the manufacturing industry in the production of molded subassemblies. Many of our customers are market leaders thanks to their superior products. The results of our close collaboration are reflected in our customers’ end products and people’s daily lives all over the world.

-

Aviation industry

Structurally advanced composite applications with superior properties for the needs of the aviation, defense and security industries. The applications include naval equipment and research and measurement equipment.

-

Health technology

We have decades of experience in the delivery of applications for the medical and healthcare industries. We manufacture molded components for hospital beds and medical devices, such as imaging devices, among other things.

-

Interior design industry

We make stylish, sound-absorbing and acoustically advanced solutions for the furniture and interior design industry.

-

Special vehicle industry

Molded solutions for the finishing touches. External parts of the vehicles, such as roof parts, rear wheel fenders and various cladding parts.

Our services

Production methods

Thermoforming of plastic

Polyurethane molding

Compression molding

Composite applications

Additional services

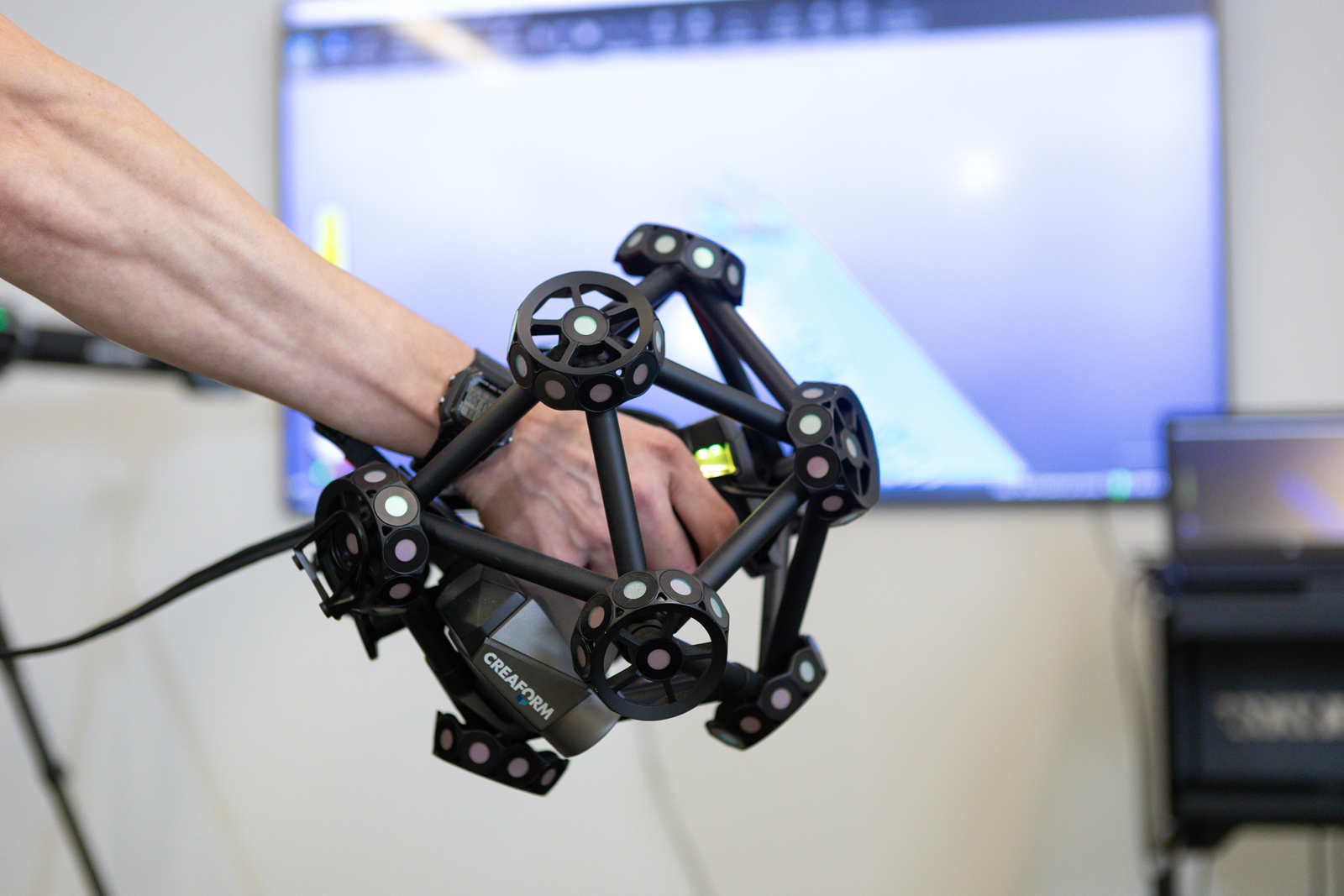

3D scanning

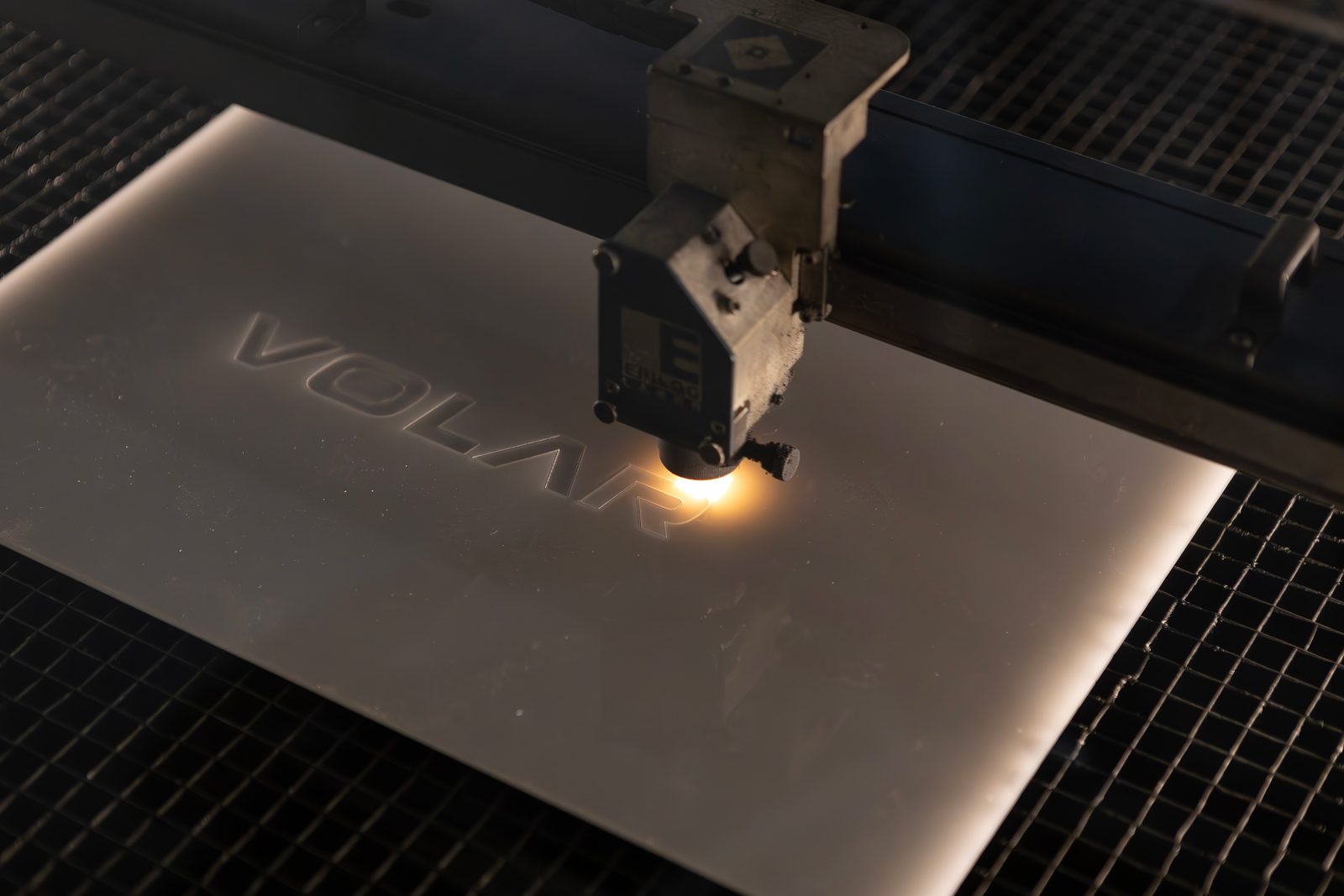

Laser marking/cutting

VOLAR on land, sea and air for decades

The same special expertise with which we made the world’s best gliders in the 1970s is used today to make individual components and subassemblies for a range of industries.

Said by our customers

Leave us a message

Our sales representatives will get back to you within two business days.